Automatic Labelers from Red Oak Label, LLC

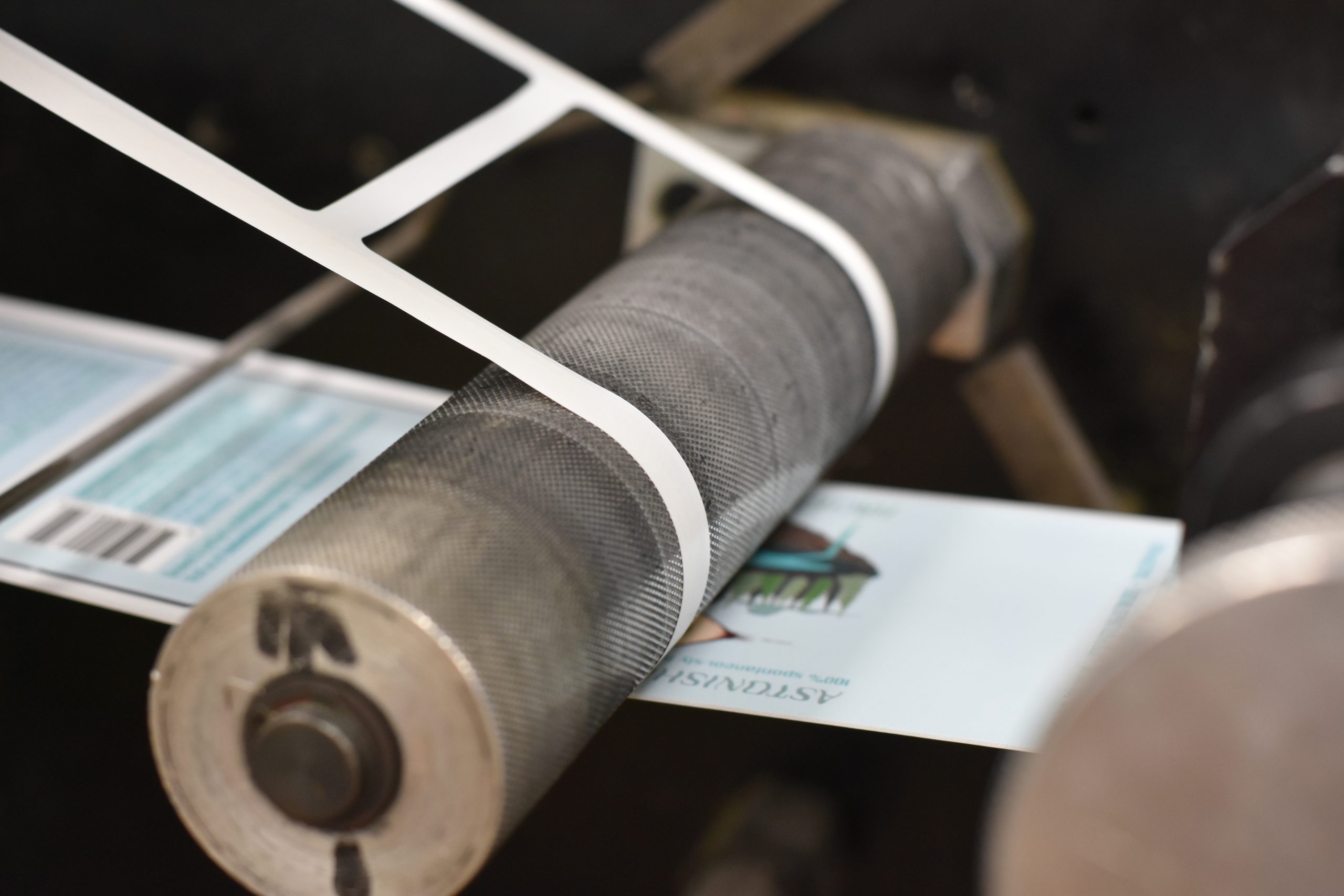

Using automatic labelers for beer labels can significantly improve the efficiency and accuracy of the labeling process. Automatic labelers are machines that apply labels to products automatically, using a variety of technologies such as roll-fed labels, pressure-sensitive labels, or glue-applied labels.

One of the main benefits of using automatic labelers for beer labels is that they can significantly speed up the labeling process. Traditional manual labeling methods can be time-consuming and labor-intensive, whereas automatic labelers can apply labels quickly and accurately, reducing the need for manual labor. This can help to increase productivity and reduce costs for breweries.

Another advantage of automatic labelers is that they can improve the accuracy of the labeling process. Human error can often lead to mislabeled products, which can be costly and potentially damaging to a brewery's reputation. Automatic labelers, on the other hand, can apply labels consistently and accurately, reducing the risk of mistakes.

In addition to increasing efficiency and accuracy, automatic labelers can also provide a number of other benefits for breweries. They can help to reduce the risk of injuries associated with manual labeling, as they do not require manual handling of labels. They can also help to improve the overall appearance of the labels, as they can apply labels consistently and accurately.

Overall, using automatic labelers for beer labels can provide a number of benefits for breweries, including increased efficiency, accuracy, and safety. If you are considering implementing automatic labelers for your brewery, it is important to carefully research and compare different options to find the best solution for your needs.

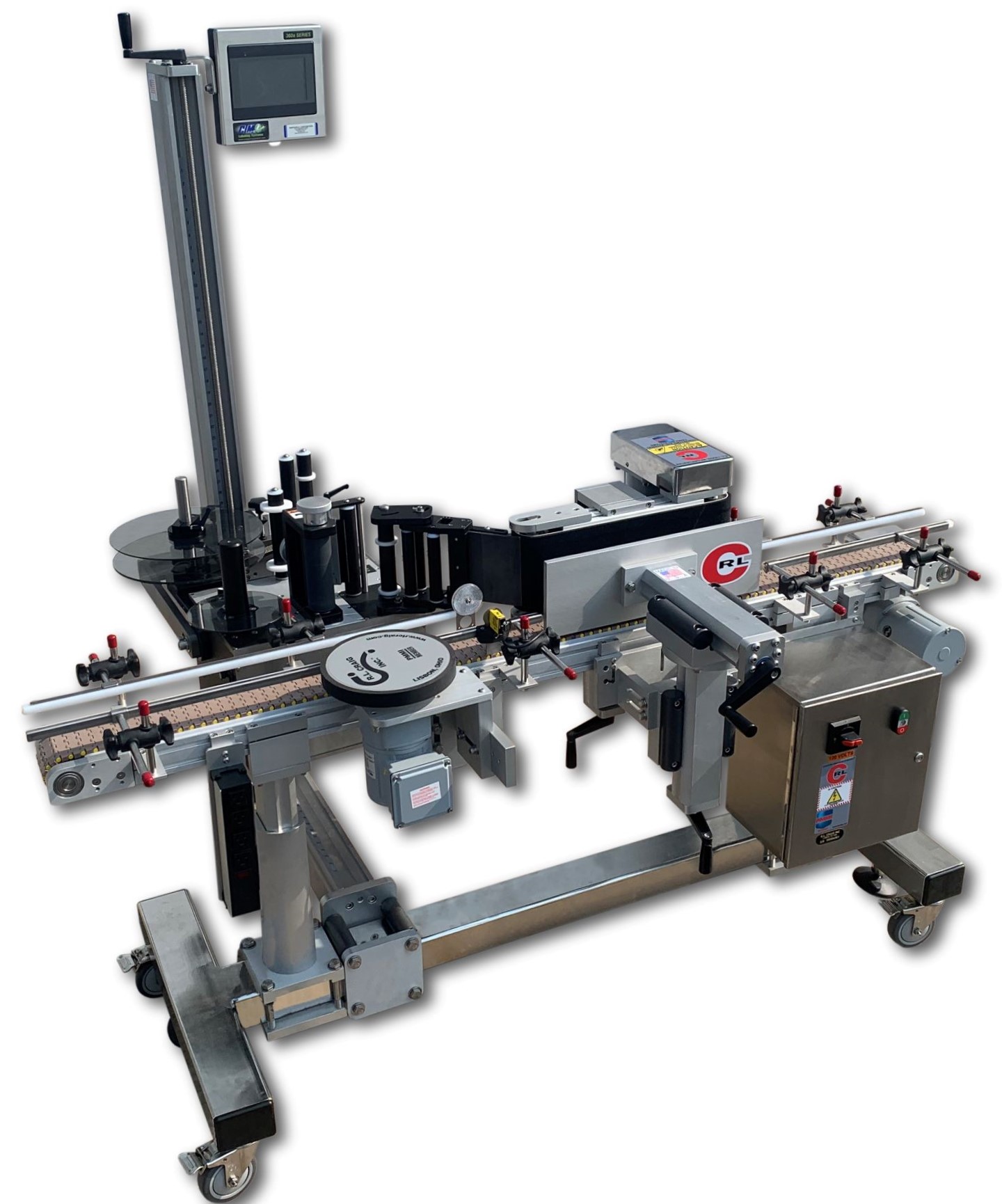

Our Beverage Can/ Bottle Labeling system offers:

- Up to 100+ cans per minute

- 120VAC power, 15 amp circuit

- Variable speed AC motors for wrap station, spacing wheel, and conveyor

- Power spacing wheel

- 6" tall x 18" long wrap station for 360* applicaiton

- 3" wide x 6' long mattop conveyor

- Anodized aluminum and powder coated steel

- Mounted on 4" locking casters for easy mobility

- Labeler mount with easy vertical and horizontal screw adjustment

- Tilt leveling block to keep label applicator level, improving label accuracy on cans and bottles

- Conveyor height can be customized to match your filler

Contact Us Today to

Request a Quote

Red Oak Label has a full design support staff to assist in any way you may need to create the perfect labeling solution for you. We can support in designing custom aluminum foil labels, lids, and tags, and we also have the ability to design tooling to ensure your labeling solution works exactly how you need it to!